M'sabata yapitayi, tinayambitsa ndondomeko yowonongeka ya mafilimu opangira mafilimu, ndipo sabata ino ndikufuna kulankhula za luso lofunika kwambiri la mafilimu.

1. Ukadaulo wokhazikika wanthawi zonse

Chifukwa cha kufunikira kogwira ntchito moyenera, mapindikidwe nthawi zambiri amakhala okwera kwambiri pama microns ochepa.Ndipo momwe mungawonetsere kuti kusamvana kwa filimuyi mumayendedwe othamanga kwambiri ndikofunikira kwambiri.Pakukonza ndondomeko sitiyenera kungoganizira zolondola za makina opangira makina, komanso kukhala ndi dongosolo langwiro la kuwongolera mikangano.

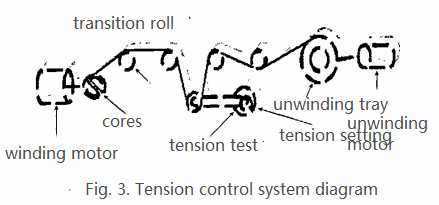

Dongosolo loyang'anira nthawi zambiri limakhala ndi magawo angapo: makina osinthira kupsinjika, sensa yodziwikiratu, makina osinthira mphamvu, makina osinthira, ndi zina zambiri.

Ma capacitor amakanema amafunikira kuuma kwina kwakanthawi pambuyo pokhotakhota, ndipo njira yoyambira yokhotakhota ndiyo kugwiritsa ntchito masika ngati kunyowetsa kuwongolera kugwedezeka kokhotakhota.Njirayi idzayambitsa kusagwirizana kosagwirizana pamene galimoto yozungulira ikuthamanga, imatsika ndikuyimitsa panthawi yokhotakhota, zomwe zidzachititsa kuti capacitor ikhale yosokonezeka kapena yopunduka, ndipo kutayika kwa capacitor kumakhalanso kwakukulu.Pamapeto pake, kupsinjika kwina kuyenera kusungidwa, ndipo chilinganizo chili motere.

F=K×B×H

Mu formula iyi:F-Kuvuta

K-Tesion coefficient

B- Kutalika kwa filimu (mm)

H-Makulidwe a kanema (μm)

Mwachitsanzo, kukankhana kwa filimu m'lifupi = 9 mm ndi makulidwe a filimu = 4.8μm.Makani ake ndi :1.2×9×4.8=0.5(N)

Kuchokera ku equation (1), kuchuluka kwa mikangano kumatha kutengedwa.Kasupe wa eddy wokhala ndi mzere wabwino amasankhidwa ngati mayendedwe ovutikira, pomwe chosalumikizana ndi maginito induction potentiometer imagwiritsidwa ntchito ngati chidziwitso chazovuta kuti muwongolere ma torque ndikuwongolera kwamagetsi opumira a DC servo motor panthawi yokhotakhota, kuti kugwedezeka. imakhazikika nthawi yonse yokhotakhota.

2. Ukadaulo wowongolera mamphepo

Kuchuluka kwa ma capacitor cores kumagwirizana kwambiri ndi kuchuluka kwa makhoti okhotakhota, kotero kuwongolera kolondola kwa ma capacitor cores kumakhala ukadaulo wofunikira.Kupindika kwa capacitor pachimake nthawi zambiri kumachitika mwachangu kwambiri.Popeza kuchuluka kwa kutembenuka kumakhudza mwachindunji mphamvu ya mphamvu, kulamulira kwa chiwerengero cha matembenuzidwe okhotakhota ndi kuwerengera kumafuna kulondola kwakukulu, komwe nthawi zambiri kumachitika pogwiritsa ntchito gawo lowerengera mofulumira kapena sensa yokhala ndi kulondola kwakukulu.Kuphatikiza apo, chifukwa chofuna kuti kusamvana kwazinthu kusinthe pang'ono momwe kungathekere panthawi yokhotakhota (kupanda kutero, zinthuzo zidzagwedezeka, zomwe zimakhudza kulondola kwamphamvu), mafunde ayenera kugwiritsa ntchito luso lowongolera.

Kuwongolera liwiro la magawo ndi kuthamangitsa koyenera / kutsika komanso kukonza liwiro losinthika ndi imodzi mwa njira zothandiza kwambiri: kuthamanga kwamitundu yosiyanasiyana kumagwiritsidwa ntchito nthawi zosiyanasiyana zokhotakhota;pa nthawi yothamanga, kuthamanga ndi kutsika kumagwiritsidwa ntchito ndi ma curve oyenera othamanga kuti athetse jitter, etc.

3. Demetallization Technology

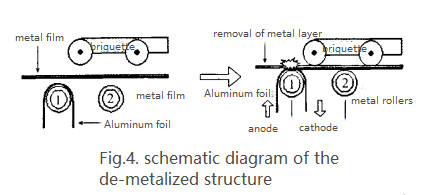

Zigawo zingapo zakuthupi zimavulazidwa pamwamba pa mzake ndipo zimafuna chithandizo chosindikizira kutentha kunja ndi mawonekedwe.Popanda kuonjezera filimu ya pulasitiki, filimu yachitsulo yomwe ilipo imagwiritsidwa ntchito ndipo filimu yake yachitsulo imagwiritsidwa ntchito ndipo zitsulo zake zowonongeka zimachotsedwa ndi njira yowonongeka kuti ipeze filimu ya pulasitiki isanayambe chisindikizo chakunja.

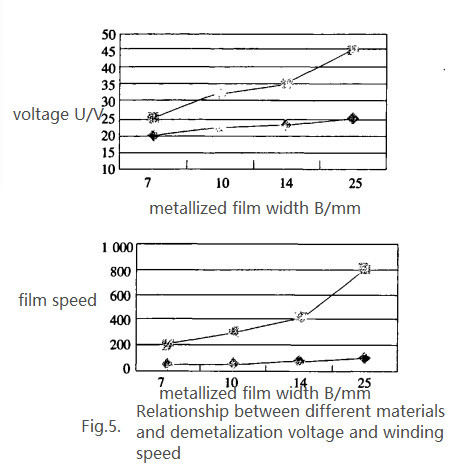

Tekinoloje iyi imatha kupulumutsa mtengo wazinthu komanso nthawi yomweyo kuchepetsa m'mimba mwake wapakati wa capacitor pachimake (panthawi yofanana ndi pachimake).Kuphatikiza apo, pogwiritsa ntchito ukadaulo wa demetalization, zokutira zachitsulo zamtundu wina (kapena zigawo ziwiri) za filimu yachitsulo zitha kuchotsedwa pasadakhale pa mawonekedwe oyambira, motero kupewa kuchitika kwa dera lalifupi losweka, lomwe lingathe kusintha kwambiri zokolola. wa coils coiled.Kuchokera pa Chithunzi.5, tinganene kuti kukwaniritsa zotsatira zofanana zochotsa.Mphamvu yochotsa idapangidwa kuti ikhale yosinthika kuchokera ku 0V mpaka 35V.Liwiro liyenera kuchepetsedwa kukhala pakati pa 200r/mphindi ndi 800 r/mphindi kuti muchepetse metalization pambuyo pakuthamanga kwambiri.Ma voliyumu osiyanasiyana ndi liwiro amatha kukhazikitsidwa pazinthu zosiyanasiyana.

4. Tekinoloje yosindikiza kutentha

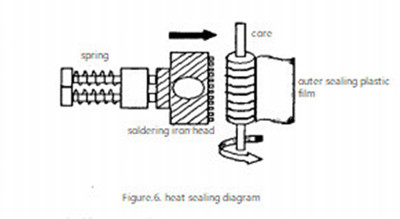

Kusindikiza kutentha ndi imodzi mwamakina ofunikira omwe amakhudza kuyenerera kwa mabala a capacitor cores.Kusindikiza kutentha ndiko kugwiritsa ntchito chitsulo chotenthetsera kutentha kwambiri kuti crimp ndi kumangiriza filimu yapulasitiki pa mawonekedwe a coiled capacitor core monga momwe tawonetsera pa Chithunzi.6.Kuti pachimake chisagwedezeke momasuka, pamafunika kumangidwa modalirika ndipo nkhope yomaliza ndi yosalala komanso yokongola.Zinthu zingapo zazikulu zomwe zimakhudza kutentha kusindikiza kutentha ndi kutentha, nthawi yosindikiza kutentha, core roll ndi liwiro, etc.

Nthawi zambiri, kutentha kwa kutentha kusindikiza kumasintha ndi makulidwe a filimuyo ndi zinthu.Ngati makulidwe a filimu ya zinthu zomwezo ndi 3μm, kutentha kwa kusindikiza kutentha kuli pakati pa 280 ℃ ndi 350 ℃, pamene makulidwe a filimuyi ndi 5.4μm, kutentha kwa kusindikiza kutentha kuyenera kusinthidwa kumtundu wa 300cc ndi 380cc.Kuzama kwa kusindikiza kutentha kumagwirizana mwachindunji ndi nthawi yosindikiza kutentha, digiri ya crimping, kutentha kwachitsulo cha soldering, ndi zina zotero.

5. Mapeto

Kupyolera mu kafukufuku ndi chitukuko m'zaka zaposachedwa, ambiri opanga zida zapakhomo apanga zida zomangira filimu capacitor.Ambiri a iwo ali bwino kuposa mankhwala omwewo kunyumba ndi kunja mawu makulidwe zinthu, liwiro lokhotakhota, ntchito demetallization ndi mapindikidwe mankhwala osiyanasiyana, ndi mayiko apamwamba luso mlingo.Pano pali kufotokozera mwachidule za luso laumisiri wamakono opanga mafilimu, ndipo tikuyembekeza kuti ndikupita patsogolo kwa teknoloji yokhudzana ndi ndondomeko ya kupanga filimu yamtundu wa capacitor, tikhoza kuyendetsa chitukuko champhamvu cha makampani opanga filimu capacitor ku China. .

Nthawi yotumiza: Mar-15-2022